Enhanced TDS

Identification & Functionality

- Chemical Family

- CASE Ingredients Functions

- Cleaning Ingredients Functions

- Industrial Additives Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- CASE Ingredients Features

- HII Features

- Industrial Additives Features

- Product Features

- Chlorine stable (up to 5% active NaOCl)

- Excellent solubilizer for nonionics in alkaline and electrolyte systems

- Excellent alkali and electrolyte stability

- Approved for use as inert in non-food pesticide formulations

- Contributes wetting properties

- Meets EPA DFE direct release criteria

- 44% active

- Chlorine stable hydrotrope offering very low, fast breaking foam

- Does not contain 1,4-dioxane

Applications & Uses

- Markets

- Applications

- Applicable Processes

- Compatible Substrates & Surfaces

- Adhesive & Sealant End Applications

- Coating End Applications

- Home Care Applications

- I&I Cleaning Applications

- Industrial Additives End Use

- Ink & Toner End Applications

Properties

- Physical Form

- Soluble In

- Appearance

- Clear, water white liquid (at 25°C)

- Type

- Anionic

- Soluble in

- 10% sodium hydroxide, 20% potassium hydroxide, Water, alcohols and glycols, Silicates, phosphates and carbonates

- Insoluble in

- Solvents and oils

- Typical Properties

Value Units Test Method / Conditions Density (at 25°C) approx. 1.05 g/ml - - Specifications

Value Units Test Method / Conditions Color max. 1 Gardner LTM# 133 Active Content 43.5 - 46.5 % - pH Value (as - is) 9 - 11 - -

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

Technical Details & Test Data

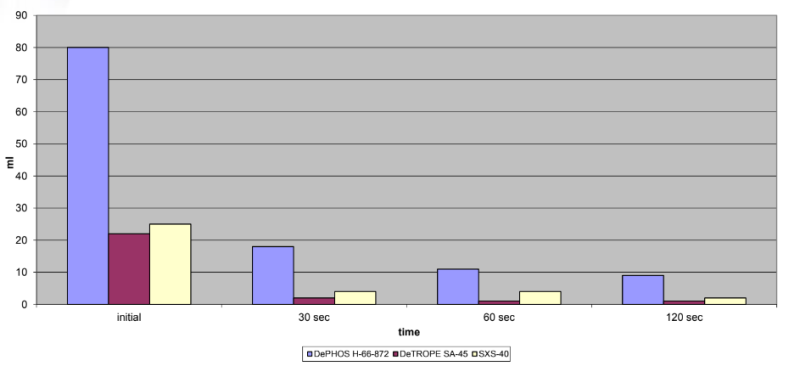

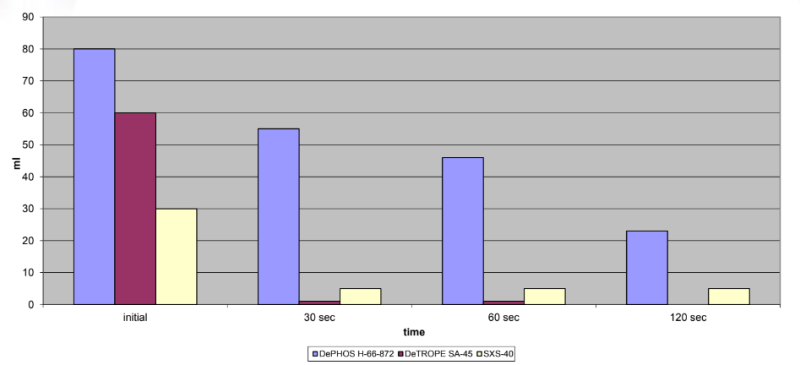

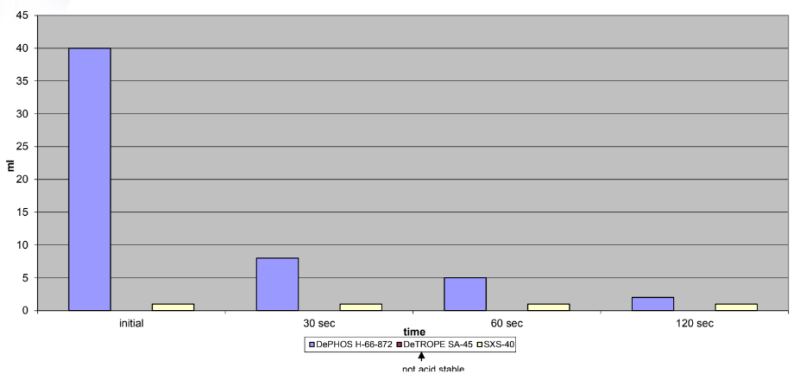

- Foam Height Data

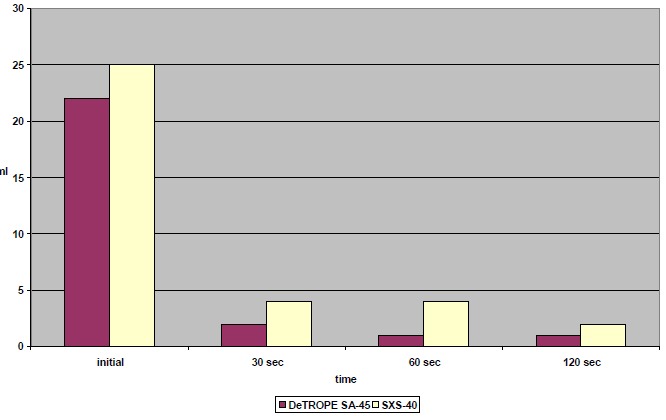

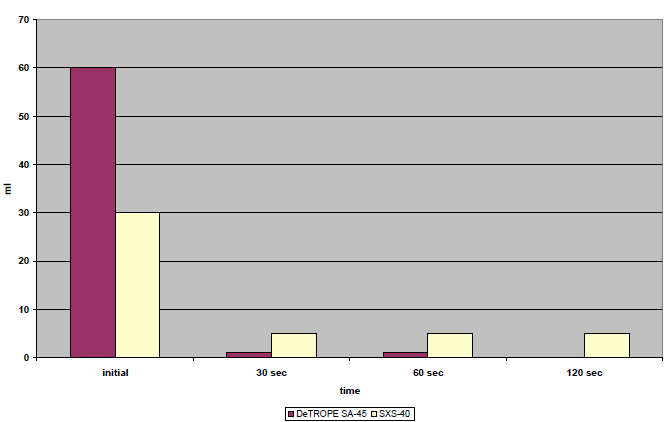

The foaming properties of DeTROPE SA-45 were determined via modified Ross-Miles, graduated cylinder shake test. The foam heights are presented in the following charts compared to sodium xylene sulfonate (SXS-40) and are reported as millimeters of foam present initially, at 30 seconds, at 60 seconds and after 2 minutes.

- Hydrotrope Foam Heights (1% surfactant 'as-is' in DI water)

- Hydrotrope Foam Heights (2% surfactant 'as-is' in 5% active NaOH)

- Cloud Point and Foam Height Data

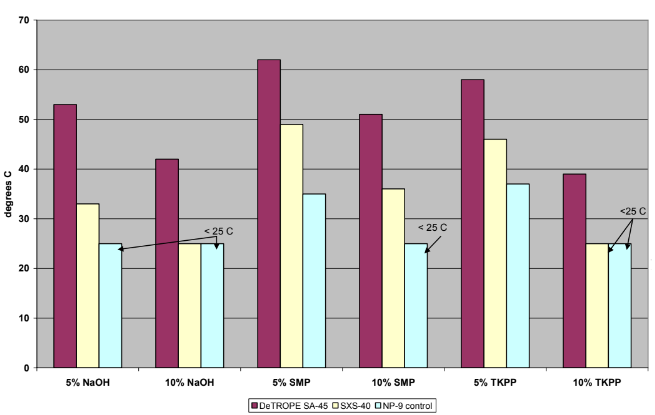

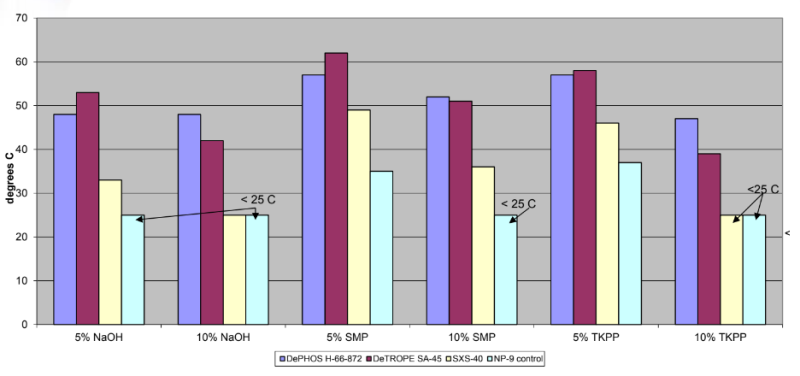

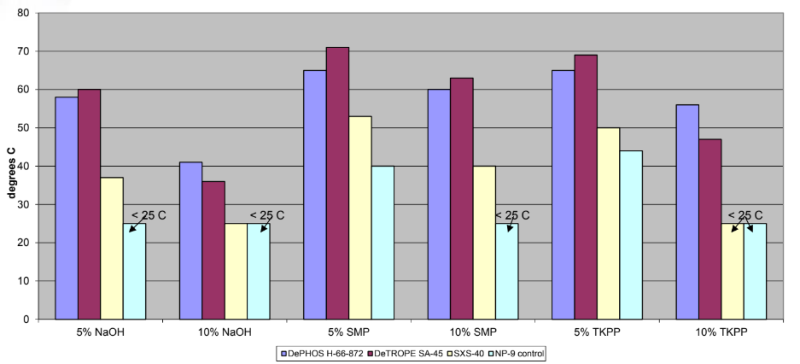

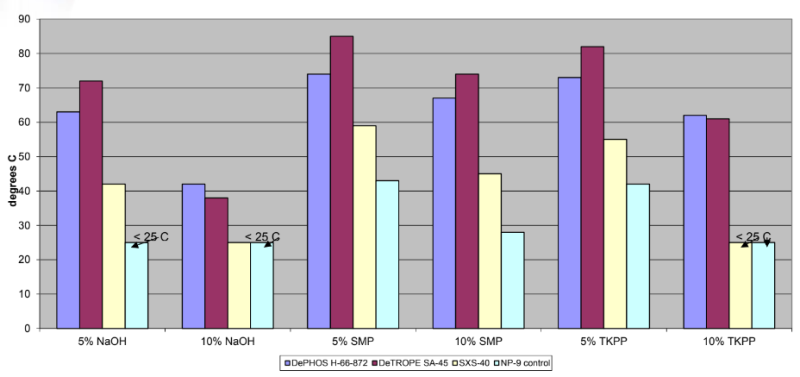

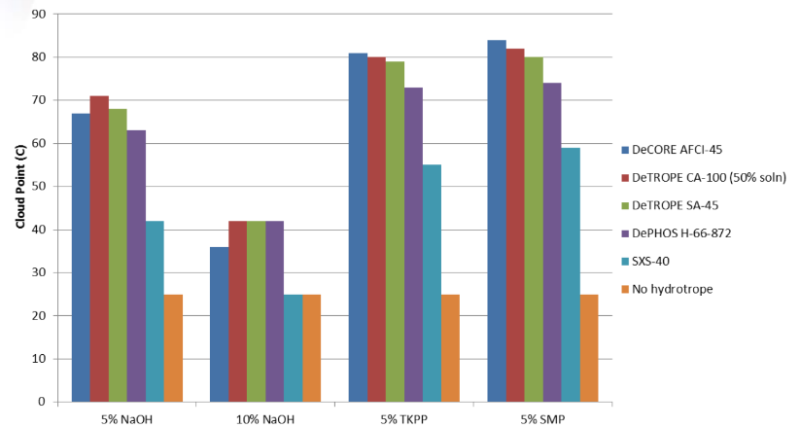

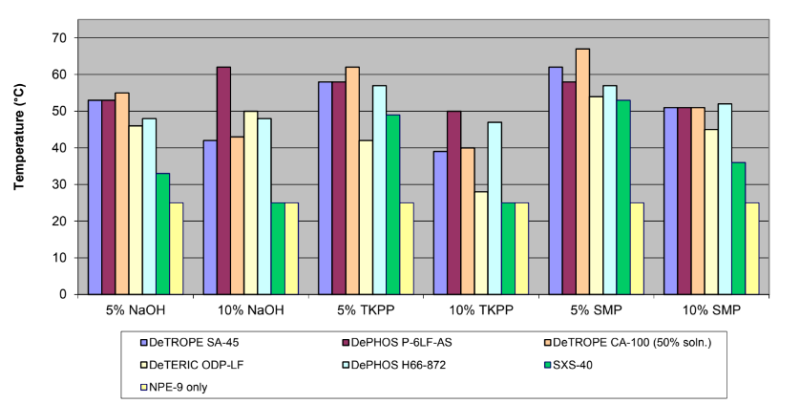

To determine hydrotroping capabilities, a series of cloud point tests were performed. The hydrotrope was solubilized in caustic or alkaline electrolyte solution to which a 9.5 mole nonyl phenol was added. Each sample was heated to the temperature at which the non- ionic clouds out of solution. The cloud point temperatures are reported in the following charts. The higher the cloud point temperature, the more efficient the hydrotrope. The control is a 9.5 nonyl phenol in each caustic and alkaline electrolyte solution with no hydrotrope added. The hydrotroping capabilities of DeTROPE SA - 45 at higher levels of NP-9.5 show similar trends.

- Hydrotrope Cloud Points (1% NP-9, 1.5% hydrotrope as-is)

Key:

- NaOH = Sodium Hydroxide

- SMP = Sodium Metasilicate Pentahydrate

- TKPP = Tetrapotassium Pyrophosphate

- SXS-40 = Sodium Xylene Sulfonate 40% active

- Hydrotrope Cloud Points (1% NP-9, 1.5% hydrotrope)

- Hydrotrope Cloud Points (3% NP-9, 2.5% hydrotrope)

SMP = Sodium Metasilicate Pentahydrate / TKPP = Tetrapotassium Pyrophosphate / SXS-40 = Sodium Xylene Sulfonate 40%

- Hydrotrope Cloud Points (5% NP-9, 3.75% hydrotrope)

- Hydrotrope Foam Heights (1% hydrotrope in DI water)

- Hydrotrope Foam Heights (2% hydrotrope in 5% active NaOH)

- Hydrotrope Foam Heights (2% hydrotrope in 5% active phosphoric acid)

Hydrotrope Cloud Point Comparison (5% NP-9 w/ 3.75% hydrotrope (as-is))

Cloud Points of Test Solutions: 5% NPE-9, 3.75% Hydrotrope (by wt.), 91.25% Electrolyte

- Cloud Points of Test Solutions: 1% NPE-9 + 1.5% Hydrotrope (as-is), 97.5% Electrolyte

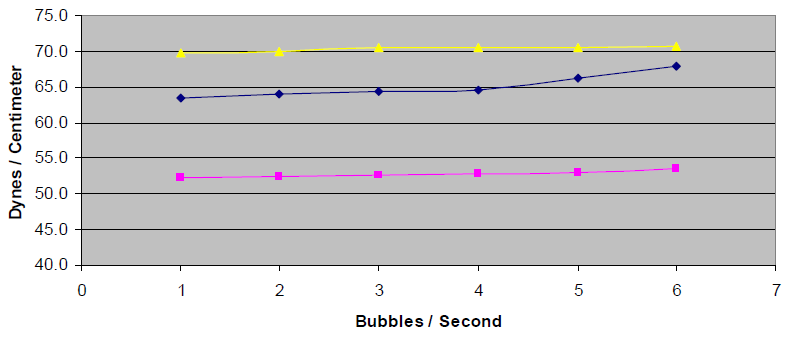

- Dynamic Surface Tension

Dynamic surface tension for DeTROPE SA - 45 was conducted at 1.0% and 2.0% by weight in deionized water at ambient temperature. Compared to SXS-40 at 2.0% by weight, DeTROPE SA - 45 provides considerably lower surface tension.

- Dynamic Surface Tension at Ambient Temperature

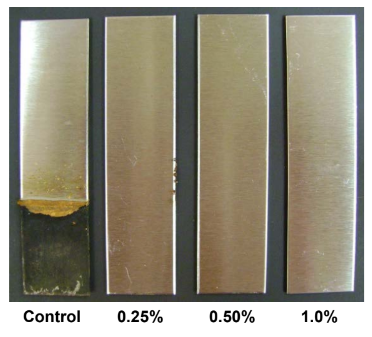

- Corrosion Inhibition Properties

Metal coupons were partially submerged in a solution containing from 0.25% - 1.0% by weight of DeTROPE SA - 45 in hard water (100ppm as CaCO₃ and 71ppm as CaCl₂) and stored in sealed glass jars at room temperature. The top halves of the panels were exposed to the vapor phase.

90 Day Results

Steel Panels: Q-Panel – Type RS – low carbon, cold-rolled steel, 0.063” thick, 1⁄2 hard

Packaging & Availability

- Supplied by