Enhanced TDS

Identification & Functionality

- Chemical Family

- CASE Ingredients Functions

- Cleaning Ingredients Functions

- Fluids & Lubricants Functions

- Industrial Additives Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- CASE Ingredients Features

- Fluids & Lubricants Features

- HII Features

- Industrial Additives Features

- Product Features

- Excellent anhydrous liquid hydrotrope for use in aqueous and powdered alkaline systems

- Excellent wetting properties in alkaline formulations

- Corrosion inhibitor for aluminum in aqueous systems at pH ≥ 7

- Moderate hard water stability

- Solubilizer for other surfactants in alkaline systems

- Low, quick breaking foam

- Good alkaline electrolyte tolerance

- Does not leave solid or waxy residue upon drying

- Provides lubricity in aqueous systems

- Non-phenolic, phosphate-free

Applications & Uses

- Markets

- Applications

- Applicable Processes

- Compatible Substrates & Surfaces

- Fluids & Lubricants Type

- Adhesive & Sealant End Applications

- Coating End Applications

- Fluids & Lubricants End Use

- Home Care Applications

- I&I Cleaning Applications

- Industrial Additives End Use

- Ink & Toner End Applications

- Use Level

- 0.1 -0.5% (in final dilution)

- Product Applications

- Synthetic coolants and cutting fluids

- High pressure alkaline detergents

- Water based paints and coatings

- Metal working fluids

- Mechanical dishwashing detergents

- Low foaming hydrotropes for use in liquid & powdered highly alkaline systems.

- Provides wetting and corrosion inhibition.

- Excellent corrosion inhibitor in aerosol cans & highly effective on aluminum.

- Not acid stable

- DeTROPE CA - 90 remains liquid at temperatures above approx.35F for easier handling.

Properties

- Physical Form

- Soluble In

- Appearance

- Clear Amber Viscous Liquid (at 25°C)

- Type

- Anionic

- Soluble in

- Water, alcohols and glycols

- Insoluble in

- Most solvents and oils

- Dispersible in

- Solvents and oils

- Typical Properties

Value Units Test Method / Conditions Density (at 25°C) approx. 1.0 g/ml - Active Content min. 99 % - Biobased Carbon Content 63.5 % - - Specifications

Value Units Test Method / Conditions Color max. 12 Gardner - pH Value (1% in D.W.) 6.5 - 7.5 - -

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

Technical Details & Test Data

- Hydrotrope Data

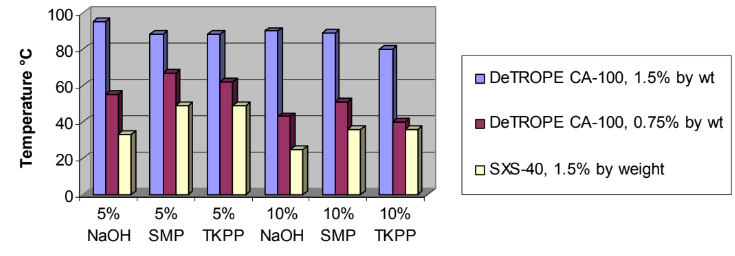

To determine hydrotroping capabilities, a series of cloud point tests were performed. The hydrotrope was solubilized in a caustic or alkaline electrolyte solution to which a

9.5 mole nonylphenol ethoxylate was added. Each sample was heated to the temperature at which the nonionic clouds out of solution. The graph below depicts the cloud point temperature. The higher the cloud point temperature, the more efficient the hydrotrope.- Hydrotrope Cloud Points: DeTROPE CA - 100 vs SXS 1% NPE-9

Key: NaOH = Sodium Hydroxide, SMP = Sodium Metasilicate Pentahydrate, TKPP = Tetrapotassium Pyrophosphate

- Dynamic Surface Tension

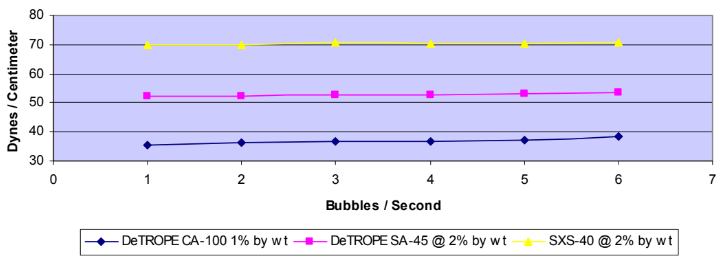

Dynamic surface tension for DeTROPE CA - 100 was conducted at ambient temperature in deionized water. Compared to SXS - 40, DeTROPE CA - 100 provides significantly lower surface tension.

- Dynamic Surface Tension at Ambient Temperature in Deionized Water

- Corrosion Testing

CORROSION TESTING USING DeFOREST CORROSION INHIBITORS

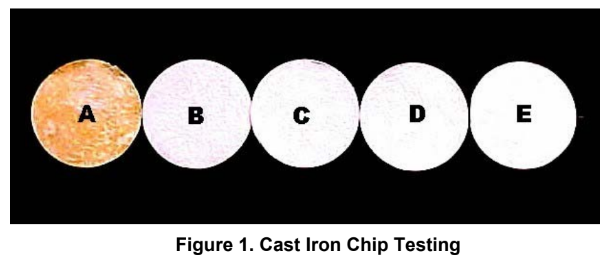

Cast Iron Chip Testing: Figure 1 depicts results of a 24 hour test using grade 35 cast iron chips tested in solution on filter paper. Each solution contained 1% by weight of corrosion inhibitor in hard water (100 ppm as CaCo₃ and 71 ppm as CaCl₂) at room temperature.

- A = Control, no corrosion inhibitor

- B = DeCORE APCI-95

- C = DeCORE IMT-100LF

- D = DeTROPE CA-100

- E = DeCORE BE-85

Submersion Testing:

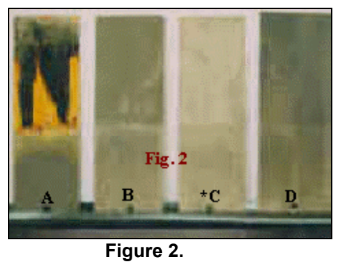

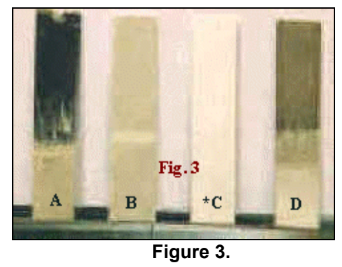

- Figures 2 and 3 illustrate the results of metal coupon submersion testing in the presence of DeFOREST Enterprises corrosion inhibitors.

- Figure 2: Panels are hot dipped Zn/Fe galvanized (unpolished), 90gms; tested for 1 year.

- Figure 3: Panels are bare aluminum at 0.063 inch thickness; tested for 2 years.

- The top halves of the panels were submerged into a solution containing from 0.5 -1% by weight of corrosion inhibitor in hard water (100 ppm as CaCo₃ and 71 ppm as CaCl₂) at room temperature. The other half of the panel was exposed to the vapor phase in closed glass containers.

Key:

- A = Control, no corrosion inhibitor

- B = DeCORE IMT-100LF at 0.5%

- C = DeTROPE CA-100 at 1.00%

- D = DeCORE BE-85 at 1.00%

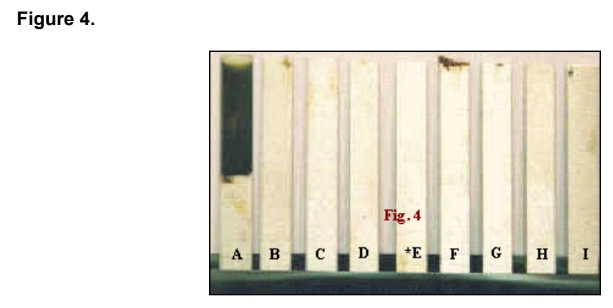

Figure 4 depicts result on ground 1/2 hard, low carbon cold rolled steel panels at 0.063 inch thickness after 2 years in the test solution. All solutions contained the following corrosion inhibitors on a ‘by weight’ basis.

- A. Control

- B. DeCORE IMT-100LF, 0.25%

- C. DeTROPE CA-100, 0.25%

- D. DeCORE IMT-100LF, 0.50%

- E. DeTROPE CA-100, 0.5%

- F. DeCORE BE-85, 0.5%

- G. DeCORE IMT-100LF, 1.0%

- H. DeTROPE CA-100, 1.0%

- I. DeCORE BE-85, 1.0%

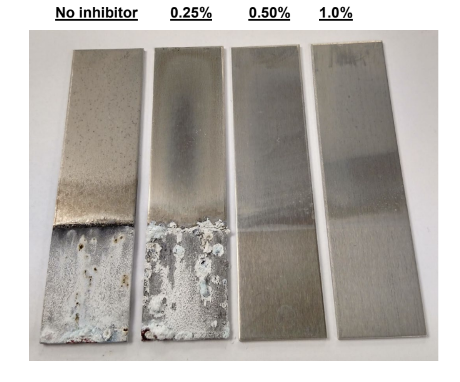

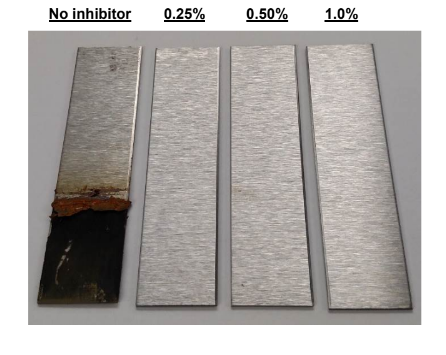

Panel Submersion Corrosion Testing:

The bottom half of each metal panel was submerged in solution containing 0.25% - 1.0% by weight of DeTROPE CA-100 in hard water (100 ppm as CaCO₃ & 71 ppm as chloride) at room temperature. The top half of the panel was exposed to the vapor phase in closed glass containers.

- #2024 Bare Aluminum, Tested for 9 months at ambient temperature

- Cold Rolled Steel, (SAE 1010), Tested for 9 months at ambient temperature

Packaging & Availability

- Supplied by