Enhanced TDS

Identification & Functionality

- Carrier

- Chemical Family

- Chemical Name

- INCI Name

- Cleaning Ingredients Functions

- Cosmetic Ingredients Functions

- Industrial Additives Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- HII Features

- Industrial Additives Features

- Product Features

- Excellent hydrotrope & solubilizing properties

- Good wetting, emulsification, & detergent properties

- High foaming properties except in the pH range of 2.4 – 4.2 (isoelectric point)

- Excellent stability in strong alkali, acid, & high concentrations of electrolytes

- Compatible with anionic, cationic & nonionic surfactants

- Approved for use as inert in non-food pesticide formulations

- Approved for food use as inert under 40CFR180.910, 920, & 930

- Low skin & eye irritation

- Low toxicity & readily biodegradable

- Exhibits corrosion protection in hard water, Hydrochloric Acid, Sulfuric, Phosphoric Acids and Acid systems

Applications & Uses

- Markets

- Applications

- Applicable Processes

- Application Format

- Compatible Substrates & Surfaces

- Hair Care Applications

- Home Care Applications

- I&I Cleaning Applications

- Skin Care Applications

- Wipes, Tissue & Towel Applications

- Product Applications

- Dispensed-as-foam products including facial cleaners, shampoo, body wash

- Hair conditioners & mild baby care products

- Wipes solutions

- Shaving creams & gels

- High foaming, salt-free surfactant with detergency, wetting, hydrotroping & emulsifying properties.

- Recommended for high foaming industrial cleaning applications as well as mild, personal care products:

- Mildness & Low Toxicity: DeTERIC LP is recommended for use as a secondary surfactant in personal cleansing and baby care products. Amphoterics are known for their mild detergency and for their ability to reduce irritation and improve the feel of skin and hair.

- Antistatic Agent: Due to its positive charge at pH <7, DeTERIC LP is electrostatically attracted to negatively charged hair and skin proteins leading to substantive, conditioning effects especially at mildly acidic pH.

- Foam Boosting & Stability: DeTERIC LP can be used to boost the foam of primary surfactants as well as increase the foam quality and density, even in the presence of oily materials and under hard water conditions.

- Efficient Hydrotrope: DeTERIC LP has the ability to solubilize hydrophobic ingredients including nonionic surfactants, oils including tea tree oil and eucalyptus, antibacterial actives, and fragrances. The benefits of formulating with DeTERIC LP include :-

- Increased formulation stability at elevated temperature

- Increased formulation stability at low temperature

- Increased formulation clarity

- Ability to formulate high solids, low viscosity products

Properties

- Physical Form

- Soluble In

- Appearance

- Light yellow liquid (at 25°C)

- Type

- Amphoteric

- Soluble in

- Water, alcohols and glycols

- Insoluble in

- Solvents and oils

- Compatible with

- anionic, cationic and nonionic surfactants

- Typical Properties

Value Units Test Method / Conditions Density (at 25°C) approx. 1.0 g/ml Biobased Carbon Content 67 % - - Specifications

Value Units Test Method / Conditions Solid Content 29.0 - 31.0 % - pH Value (as - is) 6.0 - 8.0 - - Color max. 3.0 Gardner -

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

Technical Details & Test Data

- Hydrotrope Data

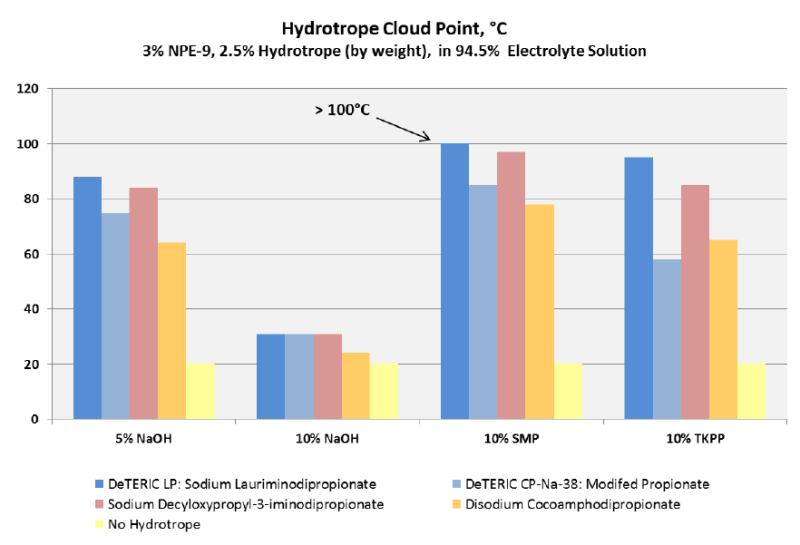

- DeTERIC LP is a superior hydrotrope compared to other high foaming amphoteric surfactants in several electrolytic systems. To determine hydrotrope capabilities, a series of cloud point tests were performed with 3% NPE-9 and 2.5% hydrotrope in the electrolytes listed below.

- The higher the cloud point temperature, the more efficient the hydrotrope.

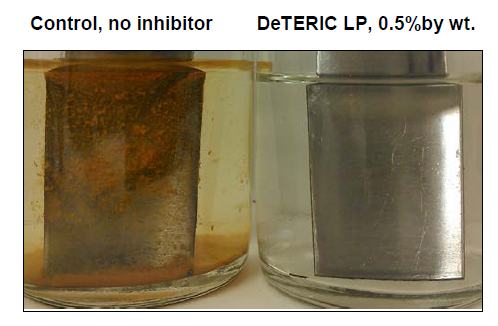

- Corrosion Inhibition Properties

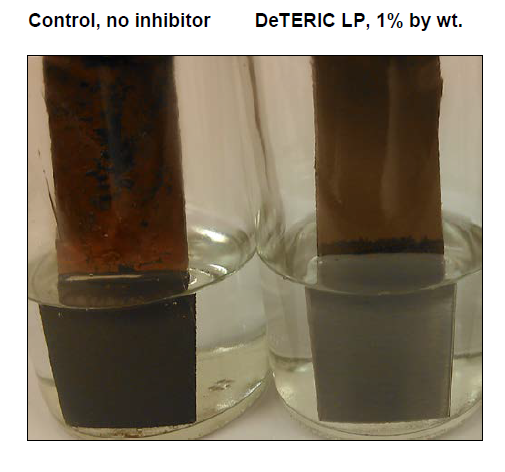

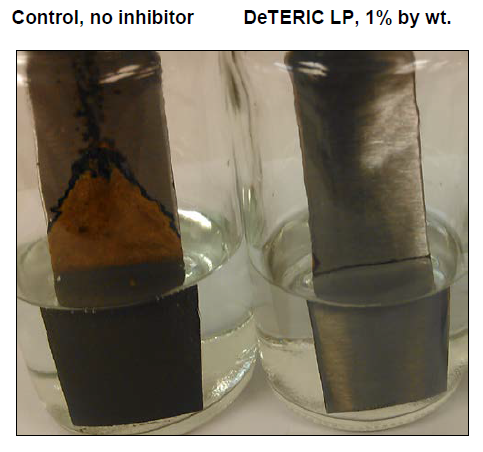

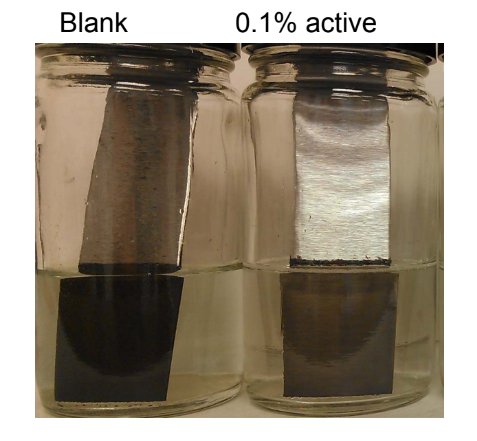

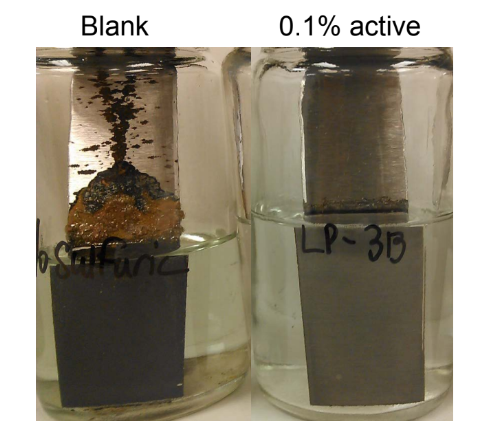

Acid Corrosion Protection: Metal panels were submerged in acid solutions and placed in sealed jars at room temperature and observed for signs of corrosion.

Cold-Rolled Steel:

- 5% active Hydrochloric Acid, 72 hours

- 5% active Sulfuric Acid, 72 hours

- 10% HCl (by weight), 72 hours

- 10% Phosphoric Acid (by wt.), 72 hours

- 10% Sulfuric Acid (by wt.), 72 hours

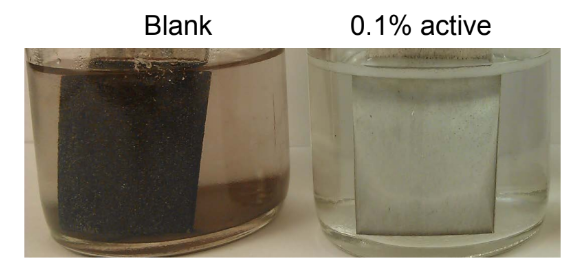

Aluminum Panels:

- 10% HCl (by weight), 24 hours

- 10% HCl (by weight), 48 hours

- 10% Sulfuric Acid (by weight), 24 hours

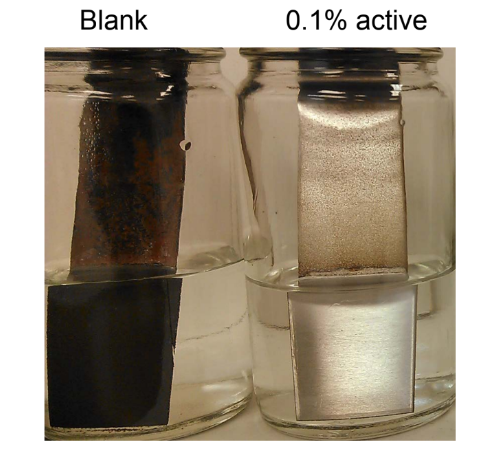

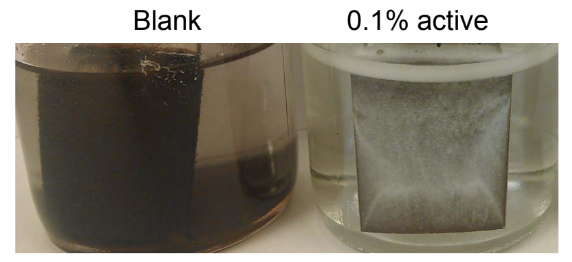

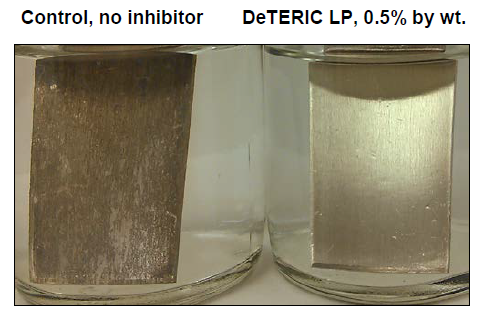

Hard Water Corrosion Protection: Metal panels were submerged in hard water (100 ppm as CaCO₃ and 71 ppm as CaCl₂) in sealed jars at room temperature and observed for signs of corrosion over time. The following photos were taken at 72 hours.

- Cold-Rolled Steel, 72 hours

- Aluminum, 72 hours

Packaging & Availability

- Supplied by