Enhanced TDS

Identification & Functionality

- Chemical Family

- CASE Ingredients Functions

- Cleaning Ingredients Functions

- Fluids & Lubricants Functions

- Industrial Additives Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- CASE Ingredients Features

- Fluids & Lubricants Features

- HII Features

Applications & Uses

- Markets

- Applications

- Applicable Processes

- Compatible Substrates & Surfaces

- Fluids & Lubricants Type

- Coating End Applications

- Fluids & Lubricants End Use

- Home Care Applications

- I&I Cleaning Applications

- Industrial Additives End Use

- Use Level

- 0.1 - 0.5%

- Product Applications

- Synthetic coolants and cutting fluids for ferrous and non-ferrous metals

- Cooling tower additive

- Water based lubricants

- Alkaline metal cleaners

- Concrete form corrosion inhibitor

- Mechanical dishwashing detergents

- Corrosion inhibitor for aqueous paints and coatings

- Corrosion inhibitor for automobile radiators

- Corrosion inhibitor for down hole drilling

- Rust preventative in aerosol cans

Properties

- Physical Form

- Soluble In

- Appearance

- Clear amber viscous liquid (at 25°C)

- Soluble in

- Water, alcohol and glycol

- Insoluble in

- Aliphatic solvents.

- Dispersible in

- Chlorinated and aromatic solvents and mineral oil.

- Typical Properties

Value Units Test Method / Conditions Activity Content min. 99 % - Density (at 25°C) approx. 1.0 g/ml - - Specifications

Value Units Test Method / Conditions Color* max. 12 Gardner - pH Value (at 1% in Distilled Water) 6.5 - 7.5 - - - Note

*darkens upon aging

- Product Properties

- Corrosion inhibitor in aqueous systems at pH ≥ 7

- Wetting and spreading properties

- Not recommended for use in acid system

- Effective at low use levels (0.1 - 0.5%) in final use dilutions

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

Technical Details & Test Data

- Corrosion Testing Using Deforest Corrosion Inhibitors

Cast Iron Chip Testing

Figure 1 depicts results of a 24 hour test using grade 35 cast iron chips tested in solution on filter paper. Each solution contained 1% by weight of corrosion inhibitor in hard water (100 ppm as CaCO₃ and 71 ppm as CaCl₂) at room temperature.

Figure 1. Cast Iron Chip Testing

A = Control, no corrosion inhibitor

B = DeCORE APCI-95

C = DeCORE IMT-100LF

D = DeTROPE CA-100

E = DeCORE BE-85Submersion Testing

Figures 2 and 3 illustrate the results of metal panel submersion testing in the presence of DeFOREST Enterprises corrosion inhibitors.

A = Control, no corrosion inhibitor

B = DeCORE IMT-100LF @ 0.5%

C = DeTROPE CA-100 @ 1.00%

D = DeCORE BE-85 @ 1.00%

Figure 2: Panels are hot dipped Zn/Fe galvanized (unpolished), 90gms; tested for 1 year.

Figure 3: Panels are bare aluminum at 0.063 inch thickness; tested for 2 years.

The top halves of the panels were submerged into a solution containing from 0.5 -1% by weight of corrosion inhibitor in hard water (100 ppm as CaCO₃ and 71 ppm as CaCl₂) at room temperature. The other half of the panel was exposed to the vapor phase in closed glass containers.

Figure 4: depicts result on ground 1/2 hard, low carbon cold rolled steel panels at 0.063 inch thickness after 2 years in the test solution.

A = Control

B = DeCORE IMT-100LF at 0.25%

C = DeTROPE CA-100 at 0.25%

D = DeCORE IMT-100LF at 0.50%

E = DeTROPE CA-100 at 0.50%

F = DeCORE BE-85 at 0.50%

G = DeCORE IMT-100LF at 1.00%

H = DeTROPE CA-100 at 1.00%

I = DeCORE BE-85 at 1.00%- Panel Submersion Testing using DeCORE IMT-100LF

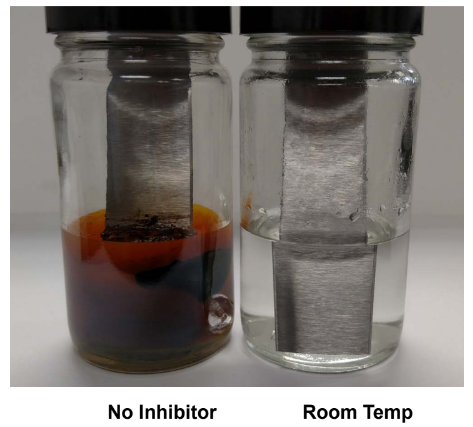

Panels were half way submerged in solutions containing DeCORE IMT-100LF in standard hard water composed of 100 ppm as CaCO₃ & 71 ppm as chloride. Panels were stored at room temperature (RT) or heat aged at 50°C as indicated in the photos below.

Cold Rolled Steel, 0.063”thickness

30 days elapsed at RT & 50°C

90 days elapsed at RT

Testing in Higher Chlorides

Panels were half submerged in a solution containing 0.5% by weight of DeCORE IMT- 100LF in hard water composed of 200 ppm as CaCO₃ & 142 ppm as chloride.

Cold Rolled Steel, 0.063”thickness, 30 days elapsed

0.5% DeCORE IMT-100LF, Steel Panels

9 Months, Standard Hard Water (71 ppm as Chloride)

Packaging & Availability

- Supplied by