Enhanced TDS

Identification & Functionality

- Chemical Family

- CASE Ingredients Functions

- Technologies

- Product Families

Features & Benefits

Applications & Uses

- Markets

- Applications

- Compatible Polymers & Resins

- Compatible Substrates & Surfaces

- Adhesive & Sealant End Applications

- Coating End Applications

Properties

- Color (Properties)

- Physical Form

- Appearance

- Yellow color liquid

- Mechanical Properties

Value Units Test Method / Conditions NX-9014 (70°C/4 hrs + 120°C/2.5 hrs)⁽¹⁾ 100 - - PMDI Content (70°C/4 hrs + 120°C/2.5 hrs)⁽¹⁾ 61.8 - - Tensile Strength (70°C/4 hrs + 120°C/2.5 hrs) 27.2 - - Shore D Hardness (70°C/4 hrs + 120°C/2.5 hrs) 76 - - Lap Shear Strength (10 on Al, 70°C/4 hrs + 120°C/2.5 hrs)⁽²⁾ 13.7 MPa - Elongation at Break (70°C/4 hrs + 120°C/2.5 hrs) 43 % - Glass Transition Temperature 37 °C - - Typical Properties

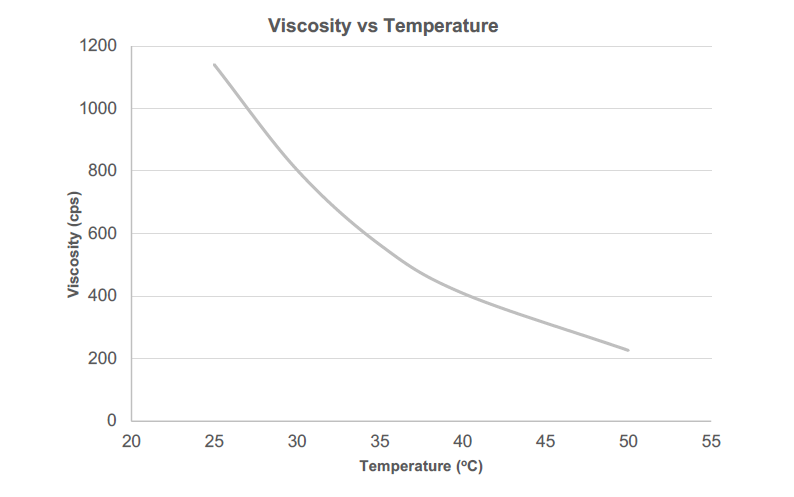

Value Units Test Method / Conditions Color max. 5 Gardner ASTM D1544 Viscosity (at 25°C) 1,000 - 1,500 cPs ASTM D2196 Hydroxyl Value 245 - 280 mg KOH/g ASTM D4274 Hydroxyl Equivalent Weight 219 g/mol - Water Content max. 0.1 % Karl-Fischer Average Functionality 4.3 - - Biological Content 64 % - - Hydrolytic Stability

Value Units Test Method / Conditions Lap Shear Strength (Control Sample)⁽²⁾ 13.2 MPa - Lap Shear Strength (after 80°C/7days Water Immersion)⁽²⁾ 5.7 MPa - Reduction in Lap Shear Strength⁽²⁾ 56.6 % - - Cured Properties

Value Units Test Method / Conditions Cure Speed (Dry hard at 25°C) max. 3 hours - Cure Speed (Dry hard at 5°C) max. 10 hours - - Note

⁽¹⁾ Polymeric MDI (PMDI): Desmodur 44V20L, PAPI 27; NCO Index: 100

⁽²⁾ Lap shear test done on blasted steel substrate or aluminum

Regulatory & Compliance

- Chemical Inventories

Technical Details & Test Data

- Viscosity Profile

Packaging & Availability

- Supplied by

Storage & Handling

- Stability and Storage

Cardolite products will absorb moisture and carbon dioxide when left in open containers, which may result in increased viscosity, discoloration, reduction of reactivity, and/or crystallization of the products. These products should be kept tightly sealed in their original containers when not in use, and stored in a cool, dry place.