Enhanced TDS

Identification & Functionality

- Chemical Family

- CASE Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- CASE Ingredients Features

- Product Features

- Phenalkamine grade NX-8101 is designed for cost effective water-based concrete epoxy primers and self- levelers that require quick return-to-service, excellent adhesion to concrete and top coats, and superior durability.

- This new low odor epoxy curing agent is supplied in water and does not contain or require any solvents in the formulation to deliver excellent performance.

- Its good compatibility with standard liquid epoxy and solid epoxy dispersions, and easy reducibility in water, broadens its use and allows for cost effective industrial coatings.

- Product Benefits

- Completely solvent-free!

- Fast cure and hardness development even at 10°C and 80% relative humidity

- Excellent adhesion over dry and damp concrete

- Compatible with standard liquid epoxy and solid epoxy dispersions

- Good formulation latitude:

- Do not demand emulsifiers

- Wide compatibility

- Systems easily reducible in water

- Excellent self-leveling properties

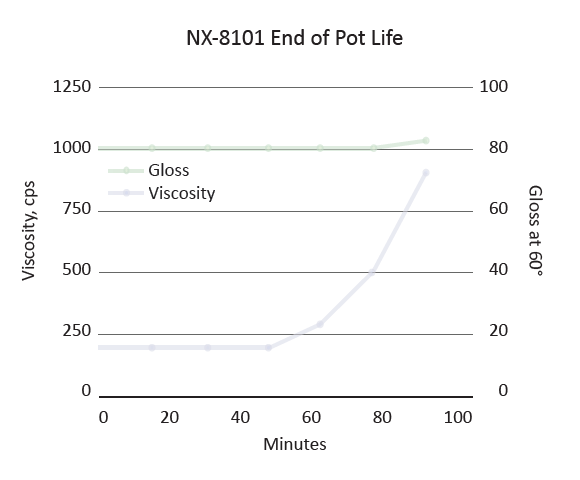

- Visible end of pot life

- Good stain resistance (household and industrial products)

- Low color, good film appearance

- Cost effective!

Applications & Uses

- Markets

- Applications

- Compatible Polymers & Resins

- Compatible Substrates & Surfaces

- Adhesive & Sealant End Applications

- Coating End Applications

- Industrial Additives End Use

- Use Level

- 130 - 155 (phr, EEW 190)

- Flexibility Pigmented Formulation

NX-8101 Competitive (WBCA)

Direct Impact 20 in-lbs 15 in-lbs Reverse Impact 4 in-lbs < 4 in-lbs - 25°C cure for 7 days before impact testing

- NX-8101 shows slightly better impact resistance than competitive WBCA. DFT of 100μ (over CRS)

- Product Applications

- NX-8101 is compatible with solid epoxy dispersions

- No additional emulsifiers are required

- Current results with BECKOPOX® EP 2384w/57W :

- Excellent film formation

- Great spray characteristics

- Excellent adhesion and blister resistance in salt spray testing with minimal corrosion inhibiting pigments.

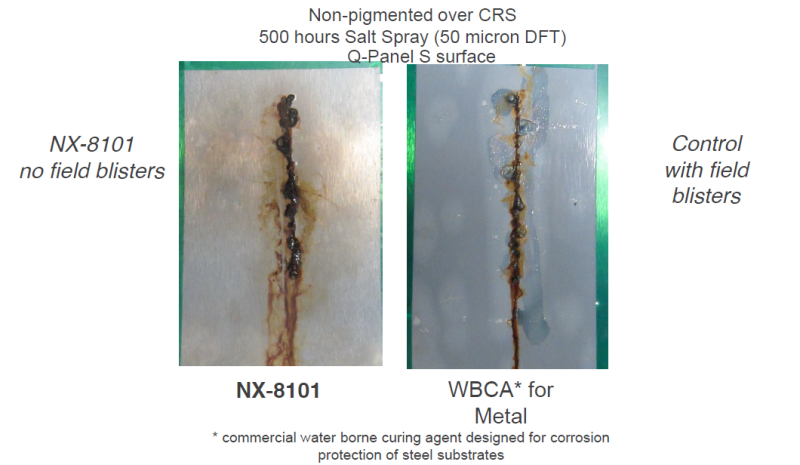

- NX-8101 For Use Over Steel

- NX-8101 exhibited no blisters away from the scribe line while the commercial waterborne curing agent showed blisters in and near to the scribe along with field blisters.

Properties

- Color (Properties)

- Physical Form

- Appearance

- Amber liquid

- Typical Properties

Value Units Test Method / Conditions Color max. 10 Gardner ASTM D1544 Viscosity (at 25°C) 20,000 - 55,000 cPs ASTM D2196 Amine Value 140 - 180 mg KOH/g ASTM D2074 Theoretical Active Hydrogen Equivalent (based on total product weight) 270 - Calculated Solid Content 48 - 52 wt.% ASTM D2369-98 Density (at 25°C) 8.61 lbs/gal ASTM D1475 - Cured Properties

Value Units Test Method / Conditions Thin Film Dry Times 8 Mils (at 25°C, at 200 micron, hard) 3 hours ASTM D5895 Thin Film Dry Times 8 Mils (at 25°C, at 200 micron, through) 4 hours ASTM D5895 Thin Film Dry Times 8 Mils (at 5°C, at 200 micron, hard) 9 hours ASTM D5895 Thin Film Dry Times 8 Mils (at 5°C, at 200 micron, through) 17 hours ASTM D5895 Liquid Epoxy Resin (EEW 190) 100 pbw - Cardolite NX-8101 Content 142 pbw - Mix Viscosity (at 25°C) 1850 cPs - Gel Time (at 25°C, 50 g) 45 minutes NTM-15 Film Appearance (at 10°C, 80% RH) Clear - Visual

Technical Details & Test Data

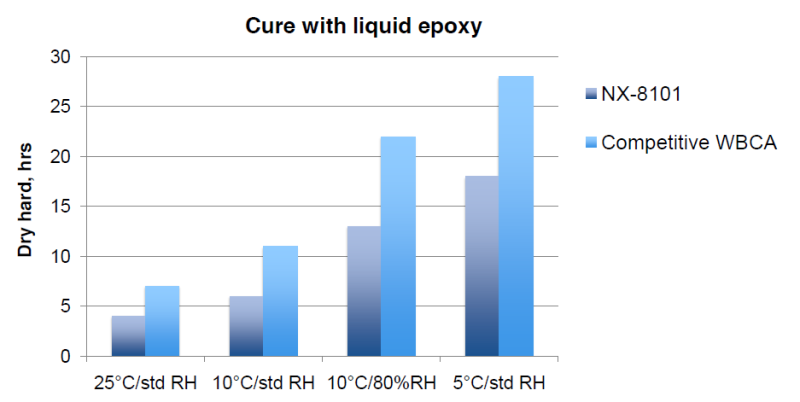

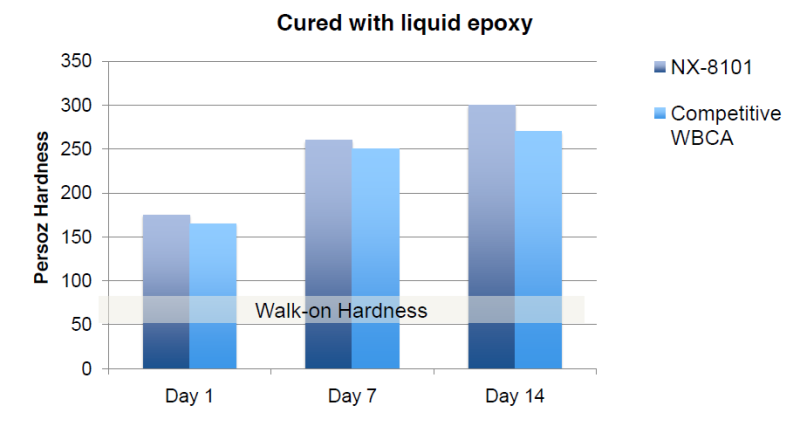

- Cured With Liquid Epoxy

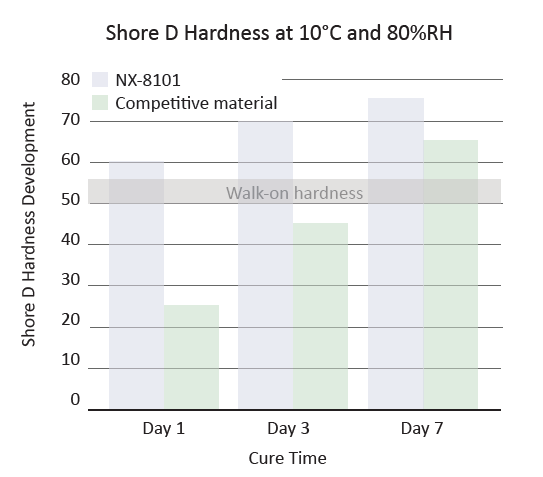

- Hardness Development at 10°C / 80% R.H.

- NX-8101 self-leveling formulation permits early walk-on hardness at low temperatures and high humidity (3 mm film thickness).

- Even under high humidity LTC conditions, NX-8101 allows quick walk-on times.

- NX-8101 Pot Life at 25°C

- Admixed with standard liquid epoxy reduced with water – total weight solids 52%

- NX-8001 shows faster cure than competitive WBCA at room and low temperatures, and low and high humidity.

- Hardness Development at 25°C

- In a self-leveling formulation, NX-8101 achieves walk-on hardness on the first day. (3 mm film thickness)

- Both systems show fast walk-on hardness in clear non-pigmented formulation.

- Adhesion to Concrete

Adhesion to Dry Concrete:

- Used 25 mil drawdown applicator to apply primer on concrete paver and cured for 7 days before adhesion test.

Adhesion to Damp Concrete:

- Concrete pavers fully immersed in water. After 72 hrs freestanding water on the top removed by blotting with paper towels.

- Pavers were ½ immersed in water and primer was applied with a 25 mil drawdown applicator.

- Coated pavers were cured for 7 days before adhesion test.

Curing Agent

Dry Concrete (psi/MPa)* Wet Concrete (psi/MPa)* Direct to concrete Direct to concrete

NX-8101 650 / 4.48 620 / 4.27 Competitive (WBCA) 625 / 4.30 523 / 3.56 *Mode of failure: in the concrete

- NX-8101 shows excellent adhesion to dry and wet concrete. (failure mode = concrete)

- Chemical / Stain Resistance

MEK Resistance 7 day cure at 25°C (200 double rubs)

Marring Break-through Softening NX-8101 Yes No Slight Competitive (WBCA) Yes No More 24 hour Spot Test at 25°C

NX-8101 Competitive (WBCA)

Mustard Slight stain Slight stain Ketchup No Effect Slight stain 3% Acetic Acid No Effect No Effect Bleach No Effect No Effect Coffee No Effect No Effect Ethanol No Effect No Effect Xylene No Effect No Effect - NX-8101 shows good chemical resistance.

- Test Conclusions

Properties NX-8101 Competitive (WBCA)

Easy Mixing with liquid epoxy Excellent Fair Fast cure at low temperatures and high humidity Excellent Poor Excellent adhesion to damp concrete Excellent Excellent Cured films are resistant to stains Excellent Good Suitable for concrete primer formulations Excellent Excellent Suitable for self-leveling formulations Excellent Fair

Packaging & Availability

- Supplied by

Storage & Handling

- Storage Condition

Cardolite products may absorb moisture and carbon dioxide when left in open containers, which could result in increased viscosity, discoloration, reduction of reactivity, and/or crystallization of the products. These products should be kept tightly sealed in their original containers when not in use, and stored in a cool, dry place that does not exceed 40°C.