Enhanced TDS

Identification & Functionality

- Chemical Family

- CASE Ingredients Functions

- Composite Materials Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- CASE Ingredients Features

- Materials Features

- Product Features

- Cardolite® Lite 2002 show good bond strength on ABC, PC and PP

- Good adhesion

- High mechanical strength

- Low viscosity

Applications & Uses

- Markets

- Applications

- Compatible Polymers & Resins

- Compatible Substrates & Surfaces

- Adhesive & Sealant End Applications

- Coating End Applications

- Composites End Use

- Composites Processing Methods

- Use Level

- 50 (phr)

- Product Applications

Application Industry End Use Process Construction Grouts, tile adhesives, anchoring adhesives, dry hanging, potting, concrete bonding, construction joints - Industrial Potable water, engineering adhesive, solar cell adhesive, aluminum bonding, putty adhesive, honeycomb panel bonding - Marine Boat hulls, panels Hand - Lay Up

Sport & leisure Canoes, kayaks Hand - Lay Up Automotive & transportation Components: seating and panels Hand - Lay Up Construction & housing Small tanks, shower trays, etc. Hand - Lay Up Other Repair kits for composite parts Hand - Lay Up Sport & leisure Boards and skis, paddles, helmets, protective apparel, suitcases RTM Automotive & transportation Truck chassis and cabins, leaf spring bars, doors and seating, engine bay components RTM Wind energy Wind turbine engine housing and other components RTM Other Auxiliary tanks for fish farming, small wastewater or sewage units, etc. RTM Marine Boats (construction and repairing) Vacuum Process

Wind energy Wind blades Vacuum Process Sport & leisure Surfboards, canoes and kayaks, tennis rackets Vacuum Process

Properties

- Physical Form

- Appearance

- Light yellow

- Mechanical Properties

Value Units Test Method / Conditions Glass Transition Temperature 86.0 °C Tensile Strength 56 MPa - Flexural Strength 115 MPa - Compressive Strength 78 MPa - Elastic Modulus 2314 MPa - Pot Life (at 25°C) 65 minutes - Mix Viscosity (at 25°C) 2717 cPs - Pot Life (at 40°C) 36 minutes - Mix Viscosity (at 40°C) 770 cPs - - Typical Properties

Value Units Test Method / Conditions Color 10 Gardner ASTM D1544 Viscosity (at 25°C) 450 cPs ASTM D2196 Theoretical Active Hydrogen Equivalent (based on total product weight) 104 - - Gel Time 51 minutes - Technology Phenalkamine - - Lap Shear Strength (EEW=190, Carbon fiber reinforced epoxy substrates: Sand paper polish+IPA clean) 17.3 MPa - Lap Shear Strength (EEW=190, Sand blasted Steel) 15 - - Amine Value 360 mg KOH/g ASTM D2074 Thin Film Dry Hard Time (at 25°C, at 200 micron) 6 hours ASTM D5895 Thin Film Dry Hard Time (at 5°C, at 200 micron) 20 hours ASTM D5895 Thin Film Dry Hard Time (at 0°C, at 200 micron) 30.5 hours ASTM D5895 Solid Content 100.0 % - Bio Content (CNSL - Based, Theoritical Estimation) 67 % - - Cured Properties

Value Units Test Method / Conditions Cure Conditions 40°C/16h+60°C/4h - - - Suggested Cure Schedule

- Curing: 4-8hrs at RT

- Post-curing: 2hrs at 100°C

- The parameters were measured in a formulation with liquid epoxy resin (EEW 188, viscosity at 25°C 10,000-14,000 cps).

- This cure schedule is recommended to fully develop mechanical, thermal and chemical resistance properties.

- Cure schedule can be adapted based on process needs.

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- LCA Results

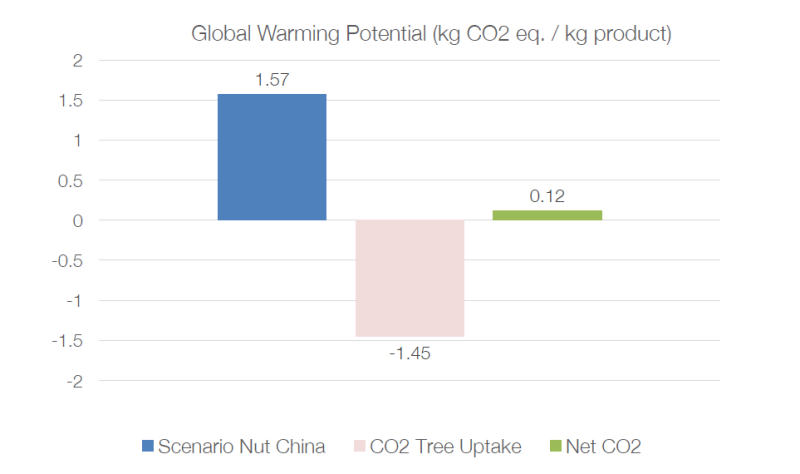

Results for each kg of LITE 2002 Produced Impact category Unit Nut China Abiotic depletion kg Sb-eq 2.21E-06 Abiotic depletion (fossil fuels) MJ 31.7 Global warming (GWP100a)* kg CO2-eq 1.57 Ozone layer depletion (ODP) CFC-11-eq 1.14E-07 Photochemical oxidation kg C2H4-eq 7.43E-04 Acidification kg SO2-eq 6.64E-03 Eutrophication kg PO4- eq 2.06E-03 *Excluding CO2 storage, only production

- LITE 2002 Global Warming Potential goes significantly down if CO2 sequestered by the cashew tree is taken into account.

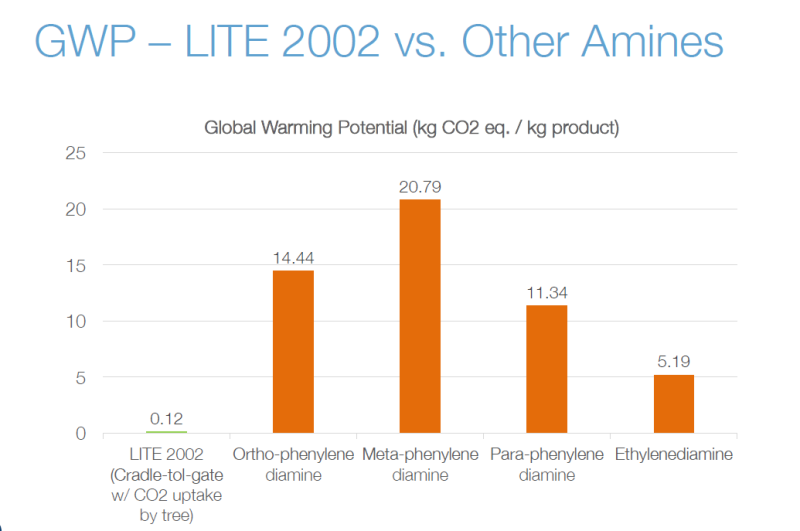

- LITE 2002 shows much lower Global Warming Potential than other petro-based amines.

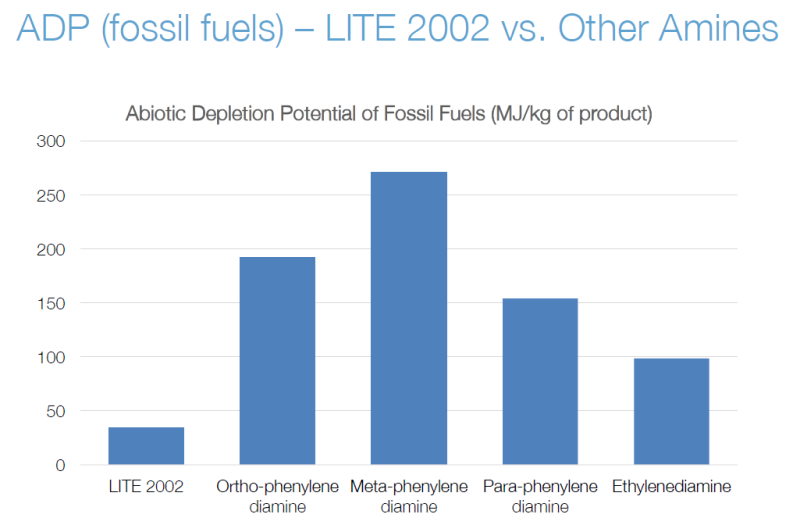

- LITE 2002 shows much lower abiotic depletion potential of fossil fuels than petro-based amines.

Conclusion

- LCA is a process to evaluate/quantify the environmental burdens associated with a product, process, or activity by identifying and quantifying energy and materials used and wastes released to the environment during their life cycle

- CNSL derivatives considered in this study have high bio-content.

- Compared to petro-based materials, Global Warming Potential goes significantly down when CNSL derivatives are used due to CO2 uptake by cashew trees.

- CNSL -based derivatives showed lower abiotic depletion potential of fossil fuels than petro -based materials.

Packaging & Availability

- Supplied by