Enhanced TDS

Identification & Functionality

- Cleaning Ingredients Functions

- Technologies

- Product Families

- Chemical Nature

Aqueous preparation made of organic acid salts and azole derivatives.

Features & Benefits

- Labeling Claims

- HII Features

- Product Features

- Fully water-soluble liquid.

- Free from bore, phosphate, molybdate, silicate or nitrite.

- Efficiently protects copper and alloys.

- Efficiently protects aluminium and alloys in contact with alkaline solutions.

- Made exclusively of substances authorized for food-contact cleaners (according to decree of 08/09/99).

Applications & Uses

- Markets

- Applications

- I&I Cleaning Applications

- Use Level

- 4 - 10% (Temporary Protection), 1 - 2% (Detergents/Degreasers)

- Product Application

Mainly used for :

- Neutral or alkaline detergents in contact with metal substrates

- Metal degreasing and cleansing operations performed during metal-working procedures

- The temporary protection of metals during their transport and storage periods

- Dosage

Can be directly added to the solution to be treated, without any pre-mixture or neutralizing step. Indicative use dosages (% of total end-solution weight)

- Detergents/Degreasers : 1 to 2%, depending on the pH.

- Temporary protection : 4 to 10% depending on the expected protection duration.

- When used for temporary protection only, the product should be diluted in soft water and applied onto metal substrates : By dipping, by spraying (depending on the spray pressure, a defoamer can be recommended) or by brushing.

Properties

- Physical Form

- Soluble In

- Appearance

- Yellow to amber limpid liquid

- Miscible in

- Water, Ethanol, Glycols, Acetone, Isopropanol

- Immiscible In

- White-Spirit

- Typical Properties

Value Units Test Method / Conditions Density (at 20°C) 1.12 - 1.16 - - Viscosity (at 20°C) 680 - 880 cPs - pH Pure (at 20°C) 8.2 - 8.8 - - Freezing Point max. -5 °C -

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Performance Data

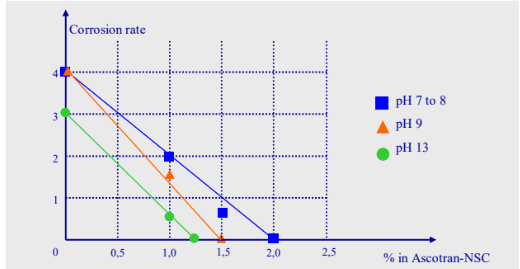

Protection by contact or short immersion

Method : DIN 51360/part 2

Medium : deionized water

Performance at different pH (adjustment with NaOH) :

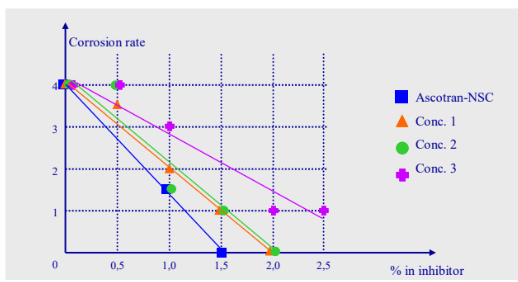

Comparative studies with our competitors’ inhibitors :

Medium : deionized water adjusted at pH-9 with NaOH if necessary.

Competitor 1 & 2 : multi-metallic liquid corrosion inhibitors.

Competitor 3 : azole-based corrosion inhibitor.

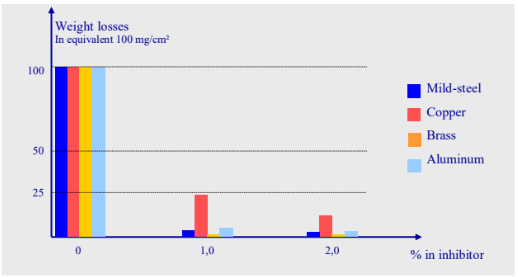

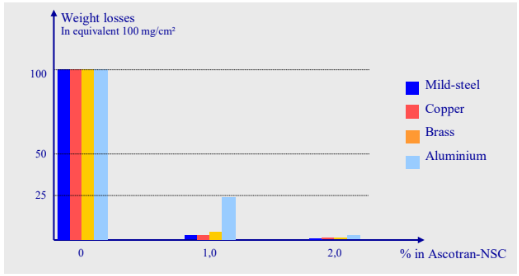

Multi-metallic protection

Method : IP329; 50°C, 330hMedium : deionized water adjusted at pH≈9 with NaOH if necessary.

Galvanic Protection

Method : ASTM D1384

Medium : corrosive water / EG mixture (see standard).

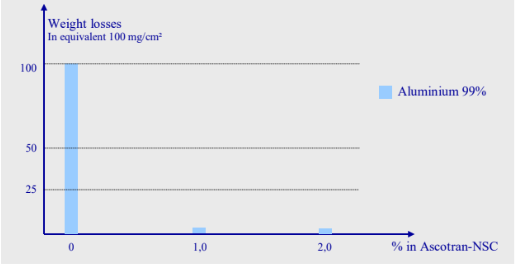

Aluminium protection in basic medium

Method : IP329; 50°C, 330h

Medium : deionized water adjusted at pH 12-13 with NaOH.

Cuprous metals protection

Method : ASTM D130, 3h, 100°C

Medium : hydrosoluble oil, ready-to-use.

A comparative study with azoles :

BZT: pure benzotriazole; TT : pure tolyl triazole0 50 ppm 100 ppm Ascotran-NSC 3b 1a 1a BZT 3b 1b 1a TT 3b 1b 1a Protection against atmospheric corrosion

Method : Climatic chamber, 25°C, 100% of humidity

Substrate : Mild-Steel or Copper 99%, immersed a few minutes in the solution added with inhibitor.

Maximum exposure duration without any corrosion of the substrate :% in Ascotran-NSC 0 % 2% 5% 10% Copper <24h >1000h >1500h >3000h Mild-Steel <24h 350h 500h >500h

Packaging & Availability

- Packaging Type

- Supplied by

- Packaging Information

- Plastic pail of 30kg net.

- Metal drum of 200kg net.

- IBC of 1000 kg net.

- Transport

No specific condition for transport. Weight and packaging size (off-pallet) :

- Pail : 1.5kg - Ø30, H50

- Drum : 15kg - Ø60, H90

IBC : 70kg - L120, l100, H120

Storage & Handling

- Shelf Life

- 2 Years

- Storage and Shelf Information

- Ideal temperature conditions: -5 to 30°C.

- Exposure: avoid direct exposure to sunlight.

- Expiration: 2 years in its original sealed drum, in the storage conditions described above. With time, the colour of the product may turn darker, but it does not modify its properties.