Enhanced TDS

Identification & Functionality

- Carrier

- Chemical Family

- Chemical Name

- CASE Ingredients Functions

- Cleaning Ingredients Functions

- Fluids & Lubricants Functions

- Technologies

- Product Families

- Chemical Nature

Aqueous preparation made of organic acid salts and azole derivatives.

Features & Benefits

- Labeling Claims

- Fluids & Lubricants Features

- HII Features

- Product Features

- Added to metal working solutions, it also protects metals during short or long immersion periods.

- Fully water-soluble liquid, safe to apply.

- Protects ferrous and non-ferrous metals.

- Prevents flash corrosion on steel.

- Forms a hydrophobic film on the metal surface, which can be coated over with conventional paint systems.

- Free of bore, phosphate, molybdate, silicate or nitrite.

- Exclusively made of authorized substances for food-contact cleaners (according to decree of 08/09/99).

- Meets PMUC standard requirements.

Applications & Uses

- Markets

- Applications

- Compatible Substrates & Surfaces

- Fluids & Lubricants Type

- Fluids & Lubricants End Use

- Home Care Applications

- I&I Cleaning Applications

- Use Level

- 2 - 15% (Temporary Protection), 0.05 - 0.2% (Hydrostatic Tests), 0.7 to 2% (Other Applications)

- Typical Application

Mainly used for:

- Synthetic or semi-synthetic hydrosoluble lubricants and metal working fluids

- Hydrosoluble hydraulic fluids

- Coolants or anti-freezes.

- Temporary protection of metal equipment or components

- during transport and dry storage.

- Protection from flash corrosion during hydro blasting.

- Protection of metal equipment during hydrostatic test procedures.

- Protection of metal equipment in long-term contact with a static aqueous solution: pipes during inactivity periods, tanks, and containers.

Can also be used in :

- Other solutions for metal machining (degreasing, stripping, polishing, cleansing under pressure).

- Neutral-to-alkaline detergents.

- Product Application

The pH of the end solution needs to be above 7 for an optimal efficiency.

Metalworking fluids

The Ascotran-L is added into water-soluble lubricants concentrates or ready-to-use solutions to get a final dosage of 50 to 5000 ppm, depending on the formulation, its pH, and the metal nature to protect.

Temporary protection

The Ascotran-L can be applied by spraying, dipping after being diluted into water, or inside the last metal working bath (washers, rinsing tanks). Dosage from 2 to 15% depending on the required protection duration.

Hydrostatic tests

The Ascotran-L is diluted into the water used for the test, at a dosage between 0.05 and 0.2% depending on the metals to protect and the test duration.

Other applications

The Ascotran-L is mixed into water-based solutions at a dosage between 0.7 to 2% depending on the solution nature and metals to protect.

Properties

- Physical Form

- Soluble In

- Appearance

- Yellow to amber limpid liquid

- Stable in

- Hard Water

- Immiscible In

- Isopropanol, White-Spirit

- Miscible in

- Water, Ethanol, Glycols, Acetone (up to 20%)

- Soluble in

- Water

- Typical Properties

Value Units Test Method / Conditions Density (at 20°C) 1.11 - 1.15 - - Viscosity (at 20°C) 600 - 800 cPs - pH Pure (at 20°C) 8.4 - 9 - - Freezing Point max. 0 °C - Foaming Power Very Low - -

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

Technical Details & Test Data

- Performance Data

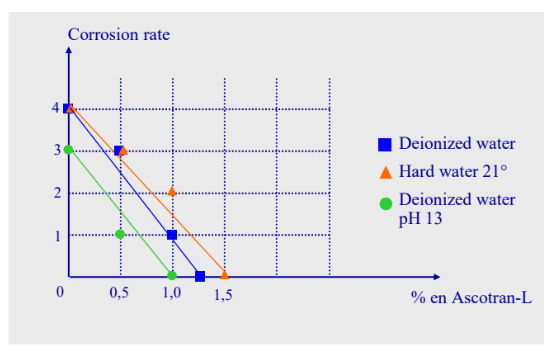

Flash Corrosion Protection

Method: DIN 51360/part2

Performance in different media

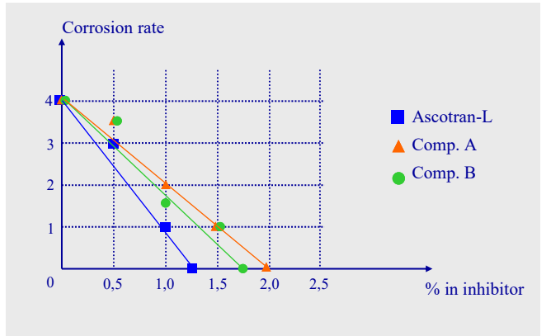

A comparative study with competitors :

Medium : deionized water

Competitors A and B : liquid corrosion inhibitors

Protection against atmospheric corrosion

Method : climatic chamber, 25°C, 100% of humidity

Substrate : mild-steel immersed few minutes in tap-water containing the inhibitor.

Max exposure time without corrosion of the substrate% in Ascotran-L 0% 2% 5% 10% Test duration without corrosion on mild-steel <24h 100h 150h >200h

Protection during immersion

Minimal protection duration of metal specimens immersed into tap-water at room temperature :% in Ascotran-L 0 % 0.05% 0.10% 0.20% 0.30% Mild-steel <1d 1 week 1 week 18 m 36 m Aluminium 99% 3d 4m 4m 4m 12m Copper 99% 3d 9m 9m 36m 36m Brass 30d 36m 36m 36m 36m Method IP329: weight loss measurement of the metal specimens immersed into deionized water, at 45°C, during 4 months.

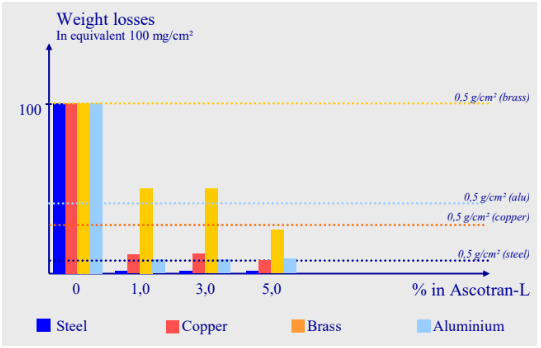

Specimens Independently :

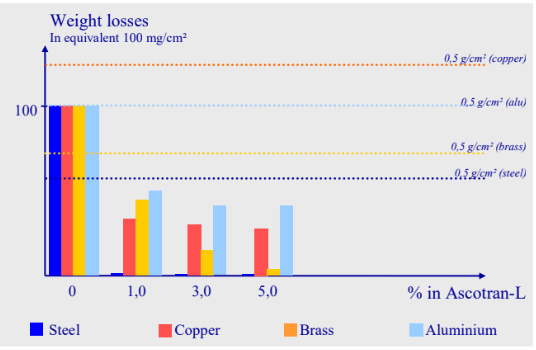

Specimens Together (Galvanic Protection) :

Packaging & Availability

- Packaging Type

- Supplied by

- Packaging Information

- Plastic pail of 30kg net.

- Metal drum of 200kg net.

- IBC of 1000 kg net.

- Transport

No specific condition for transport. Weight and packaging size (off-pallet) :

- Pail : 1.5kg - Ø30, H50

- Drum : 15kg - Ø60, H90

IBC : 70kg - L120, l100, H120

Storage & Handling

- Shelf Life

- 2 Years

- Storage and Shelf Information

- Ideal temperature conditions: 0 to 30°C.

- Exposure: avoid direct exposure to sunlight.

- Expiration: 2 years in its original sealed drum, in the storage conditions described above. With time, the colour of the product may turn darker, but it does not modify its properties.